What Is Product Development?

There’s a common statistic thrown around that 80-90% of new products fail. Although this statistic, attributed to a Harvard professor, is a myth, the actual failure rate is still fairly high, ranging between 30-49%. Successfully developing new products is crucial for business growth, yet with so many launches failing, perhaps every company should pay more attention to product development.

There are a lot of choices to make between coming up with the initial concept and introducing a product to the market. Here we break down what product development is and the various steps you can take to ensure your product launch will be a successful one.

What is Product Development?

A computer numerical control (CNC) machine is an automated manufacturing tool used for cutting, shaping, and producing high-precision items from a range of materials. CNC computers use pre-programmed sequences of commands to control the movement of cutting tools and other machinery and perform tasks such as milling, turning, drilling, routing, and grinding, among others. Various industries, such as aerospace, automotive, and industrial equipment manufacturing use CNC machining to produce complex high-quality parts and components with extreme precision.

Why Is a Product Development Strategy Important?

The high risk of failure for new products should be balanced against the opportunities they can unlock. Research by McKinsey found that the top 10 percent of companies earned 21 percent of their revenue from products and services that didn’t exist one year prior. Over the next five years, new services and products are expected to generate about $30 trillion in revenue.

With such high stakes, having a solid product development strategy is critical. It will ensure you produce something marketable that creates real value for customers. An effective strategy also lets you correctly allocate resources and time to reduce waste and overspending. By proactively incorporating customer research you can identify current needs and pain points to satisfy market demands with products people want.

Without a sound strategy to guide your decisions, you risk developing blind spots that lead to inefficiencies and misplaced efforts that never reach revenue goals.

Product Development vs. Product Management

It’s important to distinguish product development from product management. Both processes work hand-in-hand to bring ideas to market but play different roles.

Product development refers to the technical creation and execution of building a new product. This involves hands-on design, engineering, problem-solving, prototyping, and testing to achieve a functional product that meets requirements.

On the other hand, product management focuses more on business strategy, positioning, and profitability to ensure long-term market success.

What Are The Steps in Developing a Product?

While the specifics can vary across different companies, the following phases cover the most common product development process steps:

1. Generate Ideas

Identify new product opportunities through brainstorming sessions and competitive analysis. You can also use customer feedback or market research as inspiration.

Establish clear value propositions for your most promising concepts by identifying the specific consumer needs your idea addresses and the unique benefits it offers.

2. Evaluate the Idea

Evaluating the idea is crucial before investing significant resources. You will need to conduct:

- Market analysis – assesses whether there is sufficient demand for your concept.

- Technical analysis – determines whether your idea can be easily manufactured.

- Business case modeling – essential to project financial metrics related to sales potential, cost structure, and profitability outlook.

Finally, you’ll also want to create a detailed product roadmap to define major milestones and timelines, as well as establish quantifiable key performance indicators (KPIs) to track goals for sales volume, revenue, unit costs, and time-to-market targets.

3. Develop and Test Concept

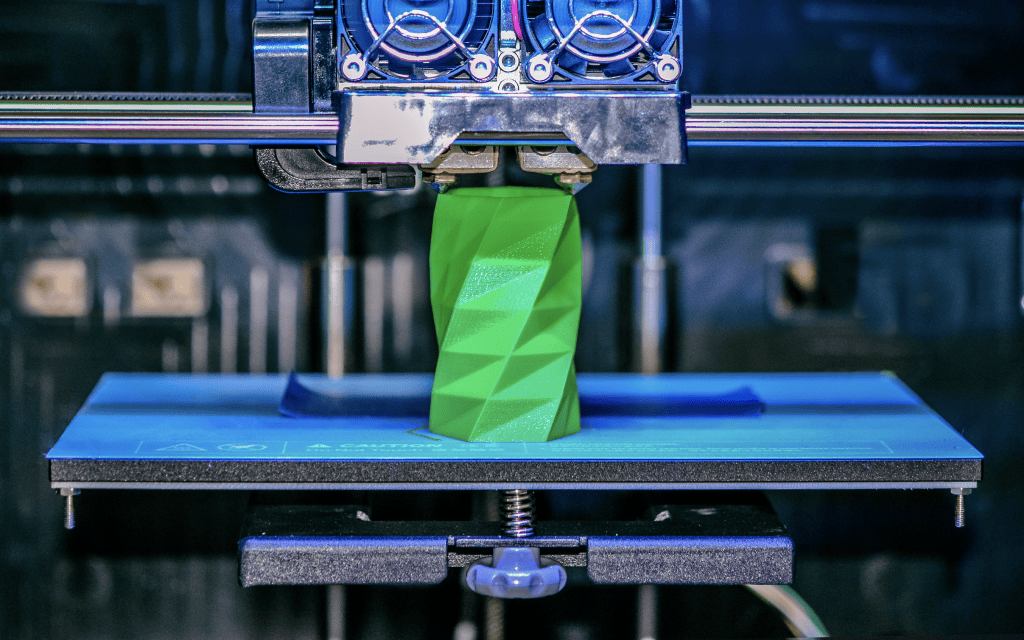

Work with your engineers and designers to finalize specifications, features, and intended user experience. Follow “design for manufacturability” principles to enable efficient future production. Create an initial prototype by partnering with manufacturing specialists. This minimum viable product only needs to feature the core functionality.

Produce the full version of your product and launch a controlled beta program. This will let you observe how customers use it in the real world and reveal any issues you will need to address. Iteratively refine your product based on user feedback until you are satisfied you have a final production-ready version.

4. Conduct Business Analysis and Plan Your Marketing Strategy

Business analysis will let you estimate the projected total market size and create sales forecast models based on pricing strategies and market dynamics. Build profitability projections and break-even analysis given the expected development, production, and marketing costs. Also, outline clear objectives and quantifiable KPIs for targeted first-year sales volumes and desired market share in key customer segments over time.

Use your analysis to formulate a comprehensive marketing strategy. This is also the stage to finalize your distribution plans, unit costs, and the pricing tactics needed to reach profit goals.

5. Design and Develop Product

Produce prototypes of your production-ready version, testing, and refining if necessary to ensure the product meets quality and regulatory requirements and customer expectations. Once satisfied, you can finally engage with manufacturers to begin preparing for full-scale production.

6. Perform Market Testing

Next, carry out controlled testing in a limited set of representative markets to generate invaluable real-world data. Monitor key metrics around sales performance, customer preferences, and pricing sensitivities. Use various customer feedback mechanisms to capture insights you can use to further hone your offering.

7. Launch Product

Perform final QA checks to validate production readiness before launch.

Execute your prepared marketing strategy – launch your campaigns, and ramp up promotions and sales efforts. Give manufacturers the go-ahead to begin mass production and alert your distribution partners that it’s time to start stocking the shelves.

After launch, continue to closely monitor key metrics around sales, revenue, and market share. Gather customer feedback to inform any adjustments to your product or marketing strategies if necessary.

Entrepreneur Daniel Peskorse leveraged MFG’s marketplace to turn his innovative Snake Bite idea into a product now sold in three international markets. By posting a Request For Quote (RFQ), he connected with vetted manufacturers who worked with him from the prototyping stage right through to production.

Count on MFG for all Your Product Development Needs

Taking a product from a bright idea to the mass market involves multiple complex steps. That’s why it’s a good idea to leverage the help of certified and vetted professionals to guide you along the way. MFG offers an interactive marketplace that will connect you with the manufacturing talent you need at each stage of product development.

We provide you with an efficient RFQ system that lets you access a global network of reviewed and rated manufacturers offering industry-specific solutions, diverse options, and custom manufacturing services. Whether you need CNC machining, injection molding, packing solutions, or assembly support, MFG can match you with the right specialists to meet your requirements.

Find out how MFG can support you throughout your product development journey today.