The 8 Benefits of Outsourcing Manufacturing

Customers expect their favorite products to always be in stock and in the quantities they might need at any moment. Many producers can struggle to keep pace with this demand using in-house resources and turn to outsourcing manufacturing as a solution. Outsourcing production brings many benefits, but it also comes with challenges that you should consider. Read on to discover the advantages of outsourcing manufacturing, ways to overcome the typical challenges, and how to find a manufacturing partner that aligns with your needs.

The 8 Benefits of Outsourcing Manufacturing

Outsourcing manufacturing offers more than just extra production capacity. When approached with careful planning, it can allow you to reduce expenditure, streamline operations, expand your product range, experiment with new technology, and more. Let’s look at the eight key advantages of adopting this approach in more detail:

1. Lower Costs

In recent years, businesses have suffered dramatic increases in materials and labor costs. While your costs may have gone up, your customers are reluctant to pay more, cutting into your profit margins. Outsourcing lets you leverage the huge economies of scale offered by specialized facilities while sidestepping hefty upfront investments in infrastructure, equipment, or human resources. By transferring those expenses to your outsourcing partner, you can allocate more of your cash flow to where it’s most urgently needed.

2. Leverage Specialized Manufacturing

Outsourcing expands the range of manufacturing options available beyond your own internal capabilities and opens up new opportunities. For example, you can order limited edition runs or products tailored to meet specific regulations for overseas markets. Having access to skilled custom manufacturers lets you experiment with new products and pursue untapped markets.

3. Scale Flexibly

Partnering with outsourced manufacturers means that you can scale up or step down production at short notice without worrying about significant investments in infrastructure or personnel, offering a flexible way to respond to changing markets or meet seasonal demand fluctuations.

4. Enhance Your Focus

Shifting to outsourced manufacturing allows you to focus more on improving your core competencies. Instead of fixating on the day-to-day ins and outs of the production process, you can concentrate your energy on perfecting your products, developing new ones, and enhancing your customer experience.

5. Distribute Risk

An outsourced manufacturer can take on responsibility for sourcing raw materials and parts, employing and training factory workers, and managing certain production and supply chain risks. Engaging multiple manufacturers allows you to diversify your options and provides additional capacity in the event of disruptions.

6. Improve Quality and Consistency

Outsourcing to specialized manufacturers with expertise in specific processes or products can lead to higher quality outputs and more consistent results. These partners often have advanced quality control systems, skilled workers, and industry certifications that ensure your products meet or exceed standards. By leveraging their expertise and resources, you can improve the overall quality and reliability of your products, enhancing customer satisfaction and brand reputation.

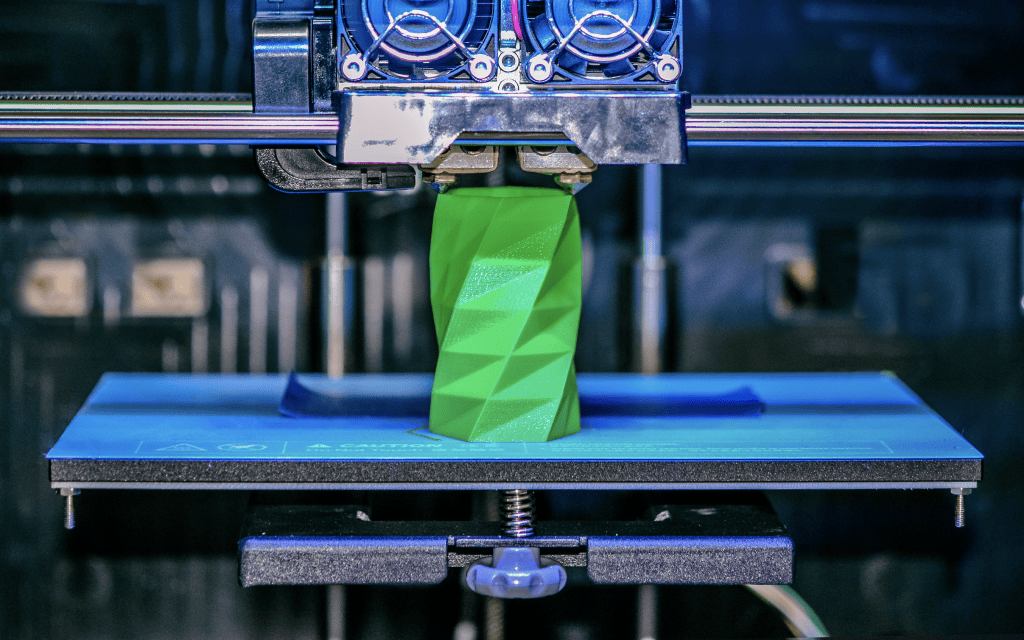

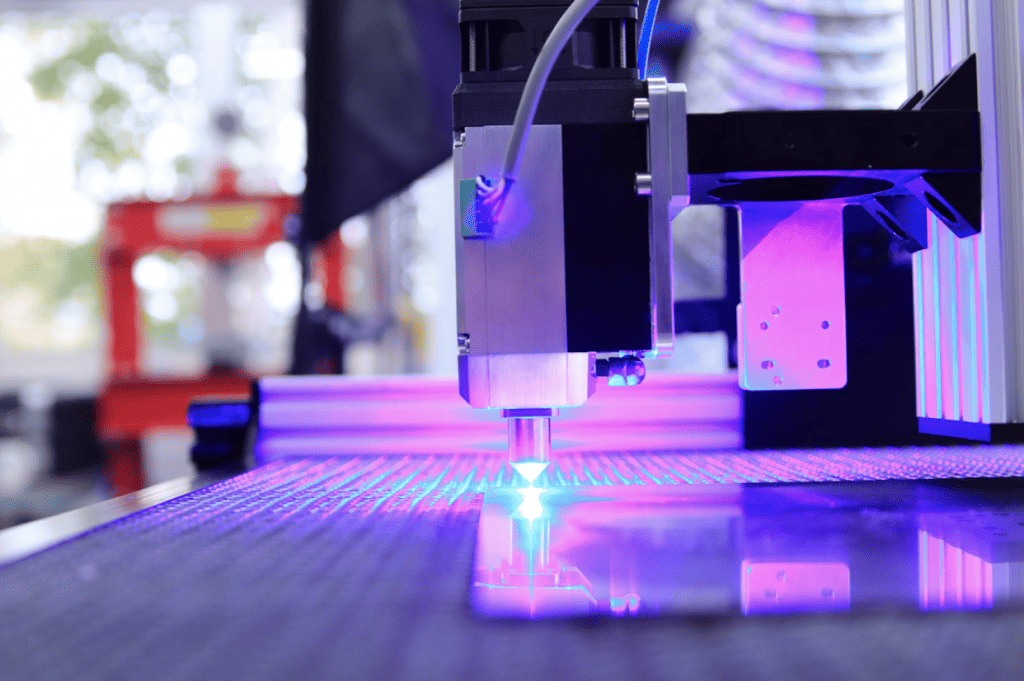

7. Access Technological Advancements

Outsourcing partners may allow your firm to access cutting-edge technology without having to make the initial investment yourself. You can share the benefits, explore new techniques, or develop innovative products without shouldering all of the risk.

8. Time to Market

By outsourcing and diversifying your manufacturing base, you can eliminate expensive and lengthy lead times. This can accelerate product launches, resulting in less time to market and more satisfied customers.

How to Overcome the Top 3 Challenges of Outsourcing Manufacturing

Despite the advantages of outsourcing, producers often raise some common concerns about the idea of engaging an external manufacturer. Here are the most frequent objections to outsourcing and how you can mitigate them:

- Security Risks: Sharing your patented designs and manufacturing techniques with multiple parties can present a business risk. This can be prevented by establishing airtight information-security requirements with the help of NDAs. For example, when you engage an outsourcing partner through MFG, NDAs are integrated into the process, ensuring the legally binding confidentiality of your information.

- Communication Logistics: If your outsourcing partner isn’t physically located close to your premises, it can introduce uncertainty around delivery timelines. Different time zones and language barriers can make communication more challenging. Thanks to onshoring and nearshoring options, you can mitigate these concerns while still taking advantage of all the benefits of outsourcing manufacturing.

- Lack of Control: Product development can include hundreds of steps, and trusting another company to make your product means giving up direct oversight of the operation. You may have concerns about design, consistency, and quality assurance. However, when you work through MFG, you can maintain tight control over the process thanks to prototyping and the ability to request frequent status updates.

The most efficient way to address all these concerns is by trusting MFG to help you find the right manufacturing partner.

How to Find the Right Manufacturer

Deciding to partner with a manufacturer is a significant step for your business, requiring the careful selection of a provider with the necessary expertise to meet your expectations. Finding the right manufacturer can be broken down into a four-step process:

- Start by clearly defining your needs: Identify and document your product requirements, including the exact specifications and quality standards it must meet.

- Use a manufacturing directory: With a precise description of your objectives, leverage a manufacturer directory to shortlist reputable manufacturers.

- Release an RFQ: Create a Request for Quote to begin receiving quotes from potential manufacturer matches.

- Conduct due diligence: Review quotes, verify references, and examine customer ratings and reviews to confirm the reliability of your potential candidates and the quality of their work.

- Set up a meeting: Following this evaluation, you can begin establishing a partnership either virtually or face-to-face.

Fortunately, MFG offers a one-stop shop to simplify your search. MFG’s comprehensive manufacturer directory provides instant access to all the details you need to consider, such as facility size, capabilities, and certifications. Our directory also provides reviews and ratings from previous customers to help guide your selection.

MFG streamlines your selection process further by enabling the creation of RFQs (Request for Quote) directly within the platform, significantly reducing the steps involved in outsourcing to a manufacturer. Register now to find your ideal outsourcing partner.