CNC Machining vs. 3D Printing: Which is Best?

In today’s fast-paced manufacturing landscape, CNC machining and 3D printing technology can ensure quick and precise parts production for various industries. But figuring out the best technology to make these parts can get tricky. That’s where understanding the use cases between CNC machining and 3D printing comes in.

What’s the Difference Between CNC Machining and 3D Printing?

CNC machining and 3D printing represent distinct manufacturing approaches with differences in process, materials, industry applications, and cost considerations. CNC machining operates through subtractive manufacturing, carving a final product from a solid block or sheet, offering precision and versatility across various materials. In contrast, 3D printing follows an additive process, layering material to build the product, excelling in swiftly creating intricate designs. The choice between these methods relies on factors like material compatibility, design complexity, industry requirements, and cost-effectiveness. Let’s explore these aspects in more detail to help you understand and select the best method for your needs.

Difference in Process: CNC vs. 3D Printing

One major difference between CNC machining and 3D printing is the manufacturing process. While the end results can be similar, the steps to get there are not.

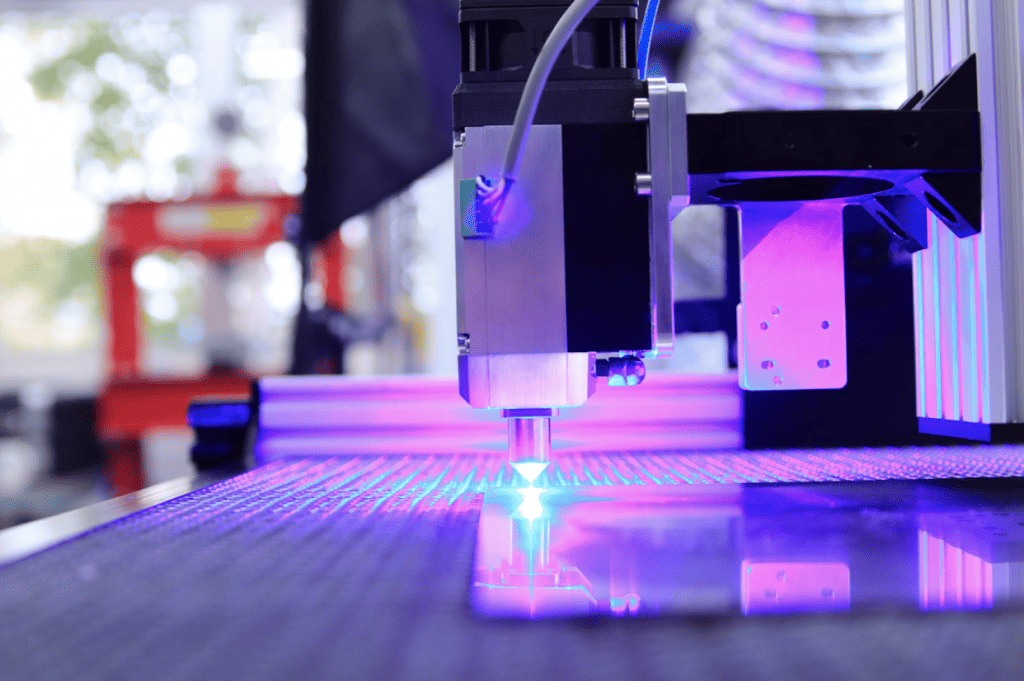

CNC Process

CNC machining is a subtractive process where a CNC machine precisely removes material from a solid block. It excels in crafting intricate and detailed parts with exceptional precision, particularly when employing 5-axis CNC machines capable of three-dimensional cutting.

While prototyping may be slower, CNC machining proves highly efficient for large-scale production, thanks to simultaneous cutting processes that contribute to time and cost savings. Its adaptability to high-volume manufacturing makes it a reliable choice for generating large quantities of parts with consistent quality and accuracy. CNC machines also accommodate a broader range of material choices and surface finish options compared to 3D printing, making them well-suited for industries requiring robust parts that can withstand significant pressure, heat, friction, and overall wear.

3D Printing Process

The 3D printing process is additive, building objects layer by layer, which is excellent for crafting intricate and complex designs. This method provides significant design freedom, allowing the creation of structures that might be challenging or impossible with traditional manufacturing. The additive process is also less wasteful than subtractive processes, since there are fewer scraps and wasted material. When applied to prototyping and small-scale production, 3D printing is typically faster due to its layer-by-layer construction, facilitating rapid iteration. However, a notable drawback is the limited range of materials and surface finish options compared to CNC machining. Careful material selection is crucial, and post-processing steps may be needed to achieve specific surface finishes, potentially altering both the appearance and functionality of the final printed object.

Difference in Materials: CNC vs. 3D Printing

CNC machining uses various metals, plastics, and composites, including durable materials like stainless steel and titanium. In contrast, 3D printing has limited material options, commonly using various plastic filaments and resins. Here’s a breakdown of the difference in material usage between CNC and 3D printing.

CNC Materials

CNC machining can use a diverse range of metals, plastics, and composites, including, but not limited to:

- Aluminum

- Brass

- Copper

- Stainless Steel

- Titanium

- Acrylic

- Wood

- MDF (Medium-Density Fiberboard)

- PVC (Polyvinyl Chloride)

- Delrin (Polyoxymethylene)

This broad selection of materials caters to applications demanding robust parts, high precision, and minimal warping. CNC machining uses more durable plastics and resins than the typical materials in 3D printing applications.

3D Printing Materials

Various types of 3D printers exist, typically using either spooled filament or liquid resin cured with UV light. Potential materials for 3D printing include:

- PLA (Polylactic Acid)

- ABS (Acrylonitrile Butadiene Styrene)

- PETG (Polyethylene Terephthalate Glycol)

- TPU (Thermoplastic Polyurethane)

- Nylon

- Polycarbonate

- PVA (Polyvinyl Alcohol)

- Woodfill

- Metal-filled Filaments

- Carbon Fiber-filled Filaments

- Extruded clay and ceramics

These printing materials come in various colors and textures, providing freedom in the appearance of the finished product.

Difference in Industries: CNC vs. 3D Printing

CNC Industries

CNC machining is known for its durability and ease of scaling up for mass production, making it a preferred choice in industries that demand robust and precisely dimensioned parts. This includes the following industries: automotive, aerospace, medical devices, electronics, tool and die making, oil and gas, defense, energy, custom furniture manufacturing, automated manufacturing, and consumer goods.

3D Printing Industries

In contrast, 3D printing has applications across virtually every industry. With the ability to swiftly create prototypes and make cost-effective adjustments, 3D printing proves invaluable for small batches, particularly in crafting ceramic parts. The process allows for extensive customization, facilitating the creation of multiple part variations before settling on the optimal design.

Difference in Cost: CNC vs. 3D Printing

Directly comparing CNC and 3D printing, 3D printing is more budget-friendly. That being said, cost-effectiveness can vary based on the scale and needs of your manufacturing. When handling smaller quantities or prototypes, 3D printing tends to be more economical, thanks to its lower initial setup and tooling costs. CNC machining is the more cost-efficient choice for larger quantities, offering superior precision, material strength, and the ability to meet specific material requirements. Considering these factors, investing in both CNC and 3D printing may prove to be a strategic approach for your business.

In the CNC vs 3D printing debate, your final choice depends on your specific manufacturing requirements. Opt for 3D printing when rapid prototypes or non-essential parts for smaller-scale projects are needed. However, if high precision or larger-scale production is necessary, CNC machining is your best option.

If you’re searching for your first— or next—CNC machinist, explore MFG’s Manufacturer Directory to discover the ideal CNC shop tailored to your manufacturing needs.