What Industries Use CNC Machines?

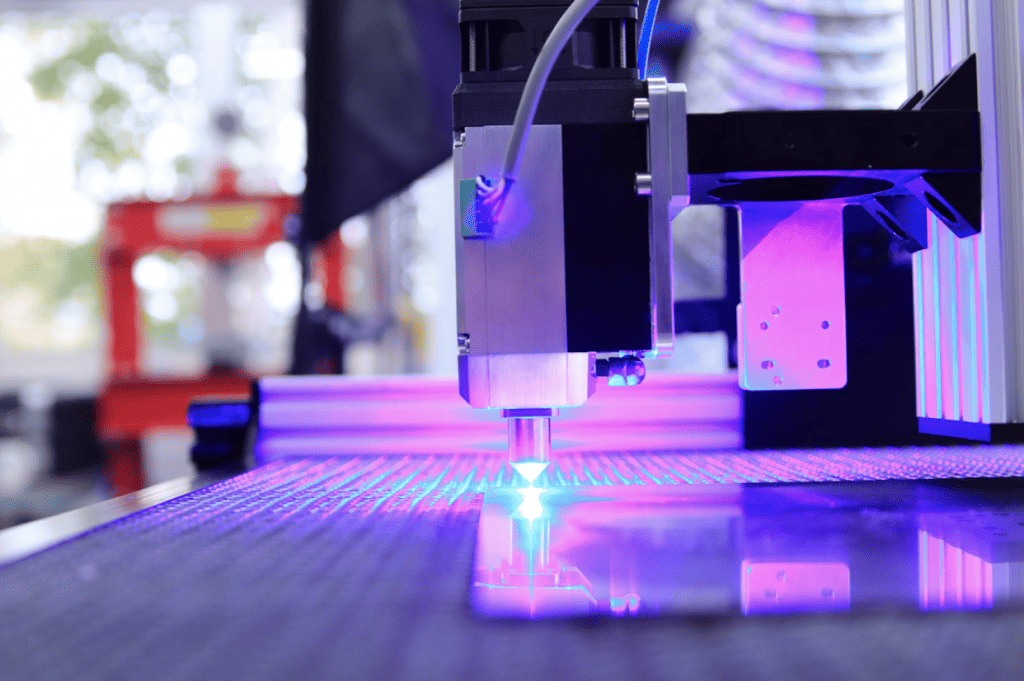

Computer Numerical Control (CNC) machines are a vital and efficient part of the manufacturing and machining industry and can be used in various ways to manufacture different parts across a plethora of industries. With their technology integration, CNC machines provide accuracy, consistency, and precision previously unattainable through manual processes. Due to the benefits of CNC machines and the intricate nature of the industries that use them, many businesses choose to custom-make the parts they need.

CNC machines can cut, shape, and create anything from prototypes to long production runs. Machines such as CNC grinders, CNC lathes, and CNC turning mills are all integrated into CNC manufacturing. CNC machines run automated from pre-programmed software and code to fabricate incredibly precise parts. A computer program directs the motion and production done by these machines. Given the automation, speed, and specificity provided by CNC machines, a variety of industries now prefer this form of manufacturing. Here we break down the types of industries that use CNC machines to create various parts.

Reasons These Industries Use a CNC Machine

Whether you are using a 3-axis or a 5-axis CNC machine, all CNC machines have these capabilities that make them popular for use.

- Precision: CNC machines are well-known for their precision and accuracy, making them the manufacturing style of choice for many industries requiring finely detailed custom parts. CNC machines offer a high degree of part complexity, tight tolerances, smooth and/or custom finishes, and offer all of this in near-perfect repeatability. If an industry is looking for precise pieces in high volumes, CNC machines are the way to go.

- Versatility: The industries that use CNC machines are often completely different from each other, yet they all can use CNC machines for their needs. CNC machines can produce parts with a wide variety of materials, including metal, plastic, wood, and more. In addition to versatility in part materials, these machines also support a wide range of part sizes and quantities.

- Customization: CNC machines are highly customizable and can produce parts outside of standard manufacturing. Entirely new shapes and parts can be imagined and designed on online programs, which are then produced by CNC machines. Slightly modifying the code or pre-programmed design will change the output as well, meaning if an industry so desired, every single piece they produce could be unique and customized.

- Efficiency: CNC machines are incredibly accurate and can maintain that accuracy even with large-scale production runs. These machines can produce substantial quantities of parts in a rapid turnaround, all with the precision and quality expected from CNC machines. The automation and quick production of CNC machines offer new levels of efficient production to industries, allowing them to save time and money overall.

Industries That Use CNC Machines

Automotive Industry

The automotive industry is a strong match for CNC machines, using them to create engine parts, transmissions, and more. The industry overall handles the design and manufacturing, as well as the repair and modification of motor vehicles. The introduction of CNC machining in the automotive industry has allowed for the more rapid production of increasingly precise and well-made cars. Furthermore, CNC machining provides the opportunity for automotive manufacturers to produce prototypes to ensure the final product is absent of any flaws.

Using CNC machines allows for the automation of the manufacturing process as well, leaving more time and space for engineers and designers to focus on new developments and innovations for the automobiles themselves. The automotive industry also taps into 3D printing alongside CNC machines for their needs.

Aerospace Industry

CNC machines are crucial to the aerospace industry, as they can create intricate components for manufacturing spanning all aviation, aircraft, and flight, as well as spacecraft and satellites. From manufacturing planes for commercial travel to military satellites for defense, the industry’s outputs are broad. Given the upswing of the current commercial aerospace economy following the downturn that came with the COVID-19 pandemic, it is more important than ever for the industry to have rapid, high-quality, and precise production of their parts.

CNC machining is the most widely used manufacturing process in the aerospace industry due to the tolerances achievable on uber-specific and highly complex parts, such as engines. CNC machines offer the timeliness and precision necessary to fulfill these requirements and ensure the safety and functionality of all productions in the industry.

Medical Industry

Like the automotive and aerospace industries, precision in the medical industry is of high importance. The medical industry also uses CNC machines, however, to create things like prosthetics and medical devices due to the customizable capabilities of CNC machines. Products like prosthetics, which are required to be highly specific to meet the needs of the patient, are ideally manufactured on a CNC machine. With CNC machines the industry can meet incredibly tight tolerances and utilize various materials.

Other medical devices and instruments, such as surgical instruments, medical machines, and more, are also produced by CNC machines given the precision granted by them. CNC machines also work hand-in-hand with other manufacturing processes that serve the medical industry. For example, CNC machines can create molds for medical supplies, which can then be used in the process of plastic injection molding to ensure consistency in the product.

Military/Defense Industry

The military and defense industry relies on high-quality, durable, reliable, and consistent technologies and products to function as efficiently as possible. Using CNC machines provides all this and more, including a wide variety of materials that can be used in the manufacturing process.

Military and defense outputs range from transportation to weaponry, made from a plethora of materials and requiring the utmost precision. The slightest errors in manufacturing on the skin of a military plane, for example, can cause the aircraft to appear on a radar. Defense parts are best developed on a CNC machine as well, not only for precision’s sake but also for the machine’s ability to mill the tough materials required for production.

Energy Industry

The energy industry includes four main categories – hydro, solar, wind, and non-renewable energy – all of which use CNC machining. The industry overall requires high-quality pieces that can withstand extreme weather and elements and continue to function with high precision, making CNC machines essential.

Certain energy industry outputs, such as wind turbine blades, are made best by CNC machines given the precise angle required on the blade for the overall functionality of the turbine. Many products required by the energy industry also must be resistant to water damage and therefore are often constructed with materials like stainless steel, which works well with CNC machines.

The precision, high quality, customization, efficiency, and versatility offered by CNC machines make this process of manufacturing the perfect route for many advanced industries to take in producing their parts. CNC machining is on the rise and is supported by platforms like MFG.com. If you are looking for a CNC Machine Manufacturer, use MFG’s manufacturer directory to outsource all of your needs.