Marketplace Pulse: Machining RFQs

Machining Manufacturers on the Marketplace are closing business each day. Get in on the action now! Create Your AccountLooking to find new customers and submit quotes on custom jobs in your special capabilities? Create your profile and grow your manufacturing business today!

If you have questions or need support, please contact us directly at support@mfg.com.

What is Machining?

Machining is the process by which material is precisely removed by mechanical means in a controlled manner by machine tools. Companies that perform machining are called machine shops. Machining is a subtractive manufacturing method which cuts away unwanted material from primary stock to form the shape of the needed part. Machining is a great process for manufacturing low to medium quantities of quality metal and plastic parts.

Machining can be segmented into three material removal methods:

- Cutting – the material is removed with single- or multi-point tools, sometimes designed of engineered for a specific predetermined part or result; examples include milling, turning and drilling (known as the 3 main machining processes).

- Abrasive – the material is removed with an abrasive material such as a grinding wheel/tool.

- Energy – materials are removed with electrical, chemical or other sources of energy; examples include electrical discharge machining (EDM) and electro-chemical machining (ECM).

Machining can also be broken into two operational categories: manual machining and CNC machining.

- Manual machining includes the traditional methods of milling and turning. The machinist sets up tooling and work holding, and then manually operates machine tools such as milling machines, lathes, drills or saws to perform various machining operations to make parts. Manual machining is the means by which all machining was once performed; today, it is usually only suitable for small lot runs with minimally complex geometry and other projects associated with prototype development.

- Computer Numerical Controlled (CNC) machining refers to the machinist using CNC controlled equipment to perform the machining operations. Types of machine tools that can be CNC-enabled are called machining centers, turning centers, Wire EDM (Electrical Discharge Machining), and multi-spindle and Swiss-style screw machines – virtually any machine tool can be built or fitted with computer numeric controls. The vast majority of machine shops today utilize CNC machining technology to improve accuracy and efficiency. The CNC machines are programmed by converting part geometry in Cartesian coordinates (X,Y, Z) and formatting those coordinates into a programming language such that the CNC controller can interpret them move the axes of the machine tool to automatically remove the required material from the work piece to form the finished machined component. CNC machining produces parts in a very consistent manner and is ideal for large quantity part runs and parts with complex geometry.

Bookmark and refresh this page often to see the newest RFQs.

Tagger Frame Assembly

RFQ ID: 1203818Machining

CNC Machining

MetauxFerreux_ALLOY_STEEL

No

1

fuel sockets

RFQ ID: 1203829POD-8898

RFQ ID: 1203835LANDIS COLLAPSIBLE HEAD - LEVER - 3ALT

RFQ ID: 1203854Machining

Milling & Turning

MetauxFerreux_CARBON_STEEL

No

80

1203841

RFQ ID: 1203841Machining

Milling & Turning

MetauxFerreux_CARBON_STEEL

No

26

Knitting Needle

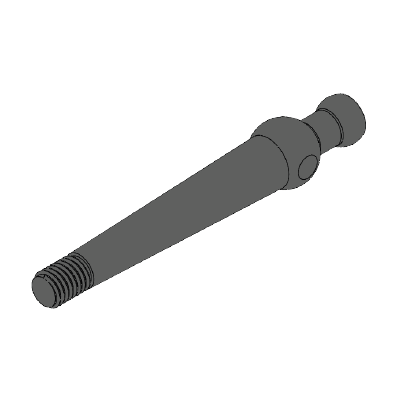

RFQ ID: 1203856Indexer Plug

RFQ ID: 1203857G10-Cryogenic and 316 SS

RFQ ID: 1203861Machining

CNC Machining

MATERIAL_PLASTICS_&_RUBBER_THERMOPLASTIC

Yes

1

Main Shaft 04

RFQ ID: 1203865Bearing Support

RFQ ID: 1203870Bracket

RFQ ID: 1203871Top Plate

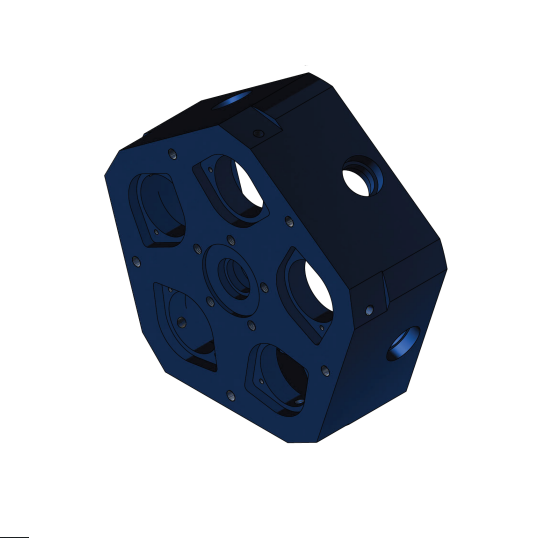

RFQ ID: 1203872Ball 01

RFQ ID: 1203875Machining

CNC Machining

MATERIAL_PLASTICS_&_RUBBER_THERMOPLASTIC

No

2,500

Ti-6AI-4V Machining Components

RFQ ID: 1203892TC Small 1203884

RFQ ID: 1203884Machining

Milling & Turning

MATERIAL_PLASTICS_&_RUBBER_THERMOPLASTIC

No

600

268_Shield_Nut

RFQ ID: 1203938Cylinder

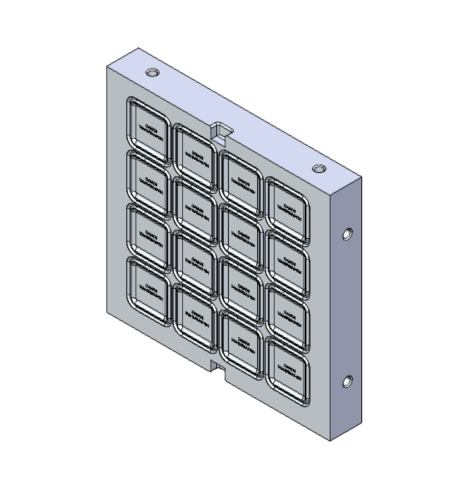

RFQ ID: 1203940NSF MAT MOLD_ROMAC

RFQ ID: 1203943Machining

CNC Machining

MetauxFerreux_CARBON_STEEL

Yes

1