-

All you Need to Know About Rapid Prototyping Plastic Injection Molding

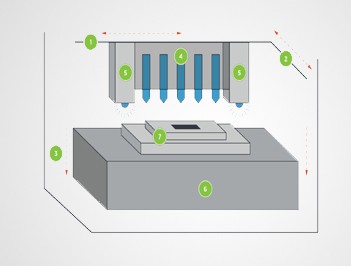

Rapid prototyping plastic injection molding is a quick and affordable method for performing low-volume injection molding for a range of different types of plastic parts. It is sometimes referred to as prototype tooling or bridge tooling.

One of the greatest ways to complete small batch orders for marketing samples, product evaluations, and process design is through rapid tooling.

Services

Provided by Plastic Prototype CompaniesTo meet your product development needs, plastic injection moulding offers high-quality prototyping, quick tooling, and low-volume manufacturing services.

Through production techniques including vacuum casting, CNC machining, plastic injection molding, and a variety of finishing services, plastic prototype companies collaborate with you to bring your product ideas to life.

To assist your objectives for developing new products, we provide the best rapid prototyping services available in the market. We take pleasure in providing a higher degree of specialized service to satisfy your precise needs. From the beginning stages of product development through mass production, our sales engineering team is here to help you.

Importance

of Plastic Prototyping ServicePlastic prototyping service guiding principles of speed and affordability enable the production of several prototype designs at once or the rapid revision and reproduction of a single prototype. Before progressing to higher-quality models for functional testing and manufacturing, these prototypes give engineers vital information that aids in design decisions.

Rapid plastic injection molding produces a set of identical components for testing with numerous backup parts that are exceptionally durable. Rapid injection molding can be utilized for temporary production during a product launch as well as high-fidelity product testing. For the initial parts, the normal lead time for quick tooling is two to three weeks.

Due to stringent material constraints or mechanical demands that cannot be addressed by additive manufacturing or machining, fast molding may be the optimum procedure for quick prototyping.

Since the typical financial and time risk is eliminated, rapid prototyping services can be utilized to test a wide range of designs and materials. By doing this, the risk associated with advancing a project without sufficient information is reduced.

How

to Find Plastic Prototype Companies Near Me?We offer the greatest plastic prototype companies near me services. Get your components sent right to your door without the trouble of sourcing, project management, logistics, or shipping by selecting from hundreds of different combinations of materials, finishes, tolerances, marks, and certifications for your order.

Sorry, there were no replies found.

Log in to reply.